Carbon Steel Limit Allowable Stress

The Code-allowable stresses are determined by the ASME Subcommittee on Materials and are listed in ASME Section II, Part D [8] of the B&PV Code. That organization also determines the allowable stress for the B31 Codes, although those stresses are not published in Section II. The basic rules for acceptance of new materials are contained in the “Guideline on the Approval of New Materials Under the ASME Boiler and Pressure Vessel Code” (found in Section II, Part D, Appendix 5) and in the similar requirements of B31.1, Appendix VI, “Approval of New Materials.”

The

allowable stresses of carbon steel material are based on properties data provided to the Subcommittee from at least three heats of the material. The properties of

carbon steel that must be included are the tensile and yield strengths at 100ºF (38ºC) intervals from room temperature to 100ºF (38ºC) above the maximum intended use temperature. Also, if the material is expected to be used in the time-dependent temperature range (that is, creep), creep rate and stress rupture data must be included starting at approximately 50ºF (10ºC) below the temperature at which the time-dependent properties might govern to 100ºF (38ºC) above the maximum use temperature. Duration of at least 6000 hours is required for the creep rupture tests.

The basis for carbon steel allowable stress can vary in different Codes, although the bases are generally the same for most power plant applications. Recent changes to the safety factor in the B&PV Code and in the B31.1 Code have resulted in increased allowable stresses (the safety factor based on tensile strength was reduced from 4 to 3.5). Although different Codes might have different requirements for the allowable stresses, the criteria used to establish the allowable stress for the Code’s Tables 1A and 1B are shown in Table 1-100 of Appendix 1 of ASME Section II, Part D [8].

These criteria follow:

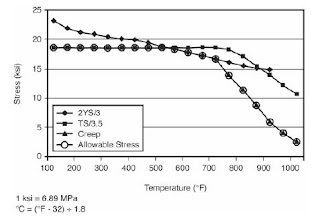

- (1/3.5) x the tensile strength at temperature (2YS/3)

- (2/3) x the yield strength at temperature (TS/3.5)

- A percentage of the creep rupture strength dependent on the testing period.

The data are used to develop trend curves. Each of these values (TS/3.5, 2YS/3, and the creep strength value) is plotted against the temperature, and the lowest value is the allowable stress for that material and that temperature. See Figure below for an example plot for SA-516 Gr. 65.

Carbon steel allowable stresses must be obtained from the applicable Code. The allowable stresses are subject to change because they are a function of the safety factor used in the applicable Code and of the properties of the material specification (which are also subject to change). There are also differences in the temperature limits for the materials. Due to the fact that the strength requirements and the pressure-temperature tables of the standards are subject to change, particular attention should be paid to the edition reference of the material specification or referenced standard. Prior to referencing a later edition, the Code committees review these changes and adjust to the carbon steel allowable stresses accordingly. If stress work more than allowed carbon steel may can be cracked.

Next

Carbon Equivalence